The KS certification is a voluntary certification system that conducts strict audit on companies that can continuously and stably produce products above the Korean Industrial Standards (KS) level. The KS certification mark can be affixed when products passed the strict audit. The system promotes the simplification and transparency of transactions and processes through the promotion of standardized products and services, which not only protects consumer rights and public safety, but also eliminates the need for quality confirmation and other procedures when countries, enterprises and public organizations purchase products, saving money and time.

Certification mark

According to the provisions of the Korean Industrial Standardization Law, KS certification is divided into product certification and service certification. All products or services selected as KS certification objects need to go through factory inspection, product inspection, or service inspection according to the corresponding KS standards. After passing the inspections, a KS certificate can be issued. CIRS currently provides KS product certification, the following content is only for reference during product certification.

The KS mark certification can only be obtained for product varieties that are designated by the Korea Institute of Technical Standards and are deemed necessary for the popularization and promotion of national standards. As of 2008, there are more than 800 kinds of products designated with the KS mark, and more than 6,000 factories have obtained more than 12,000 KS certifications. The factory audit standard adopted in the KS mark certification process is called "KS certification audit standard". The audit standard specifies the specific requirements of each item in detail. Therefore, it is recommended that enterprises purchase the audit standard, fully understand the requirements of the audit standard, and prepare according to its content, which can effectively promote the certification business.

KS certified product preferential system

- Priority is given to purchasing KS-certified products by the Korean state, local governments, government investment agencies, and public organizations when purchasing products (Article 25 of the Korean Industrial Standardization Act)

- Part or all of the content of certification, testing, and formal licensing that can be exempted from safety certification (Article 26 of the Industrial Standardization Law)

- Preferential bidding contract in international bidding for countries (Article 23 of the National Contract Law Enforcement Decree)

- Quality inspection of building materials can be omitted (Article 91 of the Enforcement Decree of the Construction Technology Promotion Act)

KS certification advantages

- Enhance the competitiveness of certified enterprises

- Protect consumer rights and public safety

- Promote facilitation and transparency of transaction supply

- A basis for purchasing the product

Preparations for the applicant company

KS certification is a certification body that will evaluate whether the company promotes internal standardization activities and quality management activities in order to continuously establish a quality system and continue to produce products that exceed the requirements of the Korean industrial standard. Therefore, the applicant company must be operated and managed for more than 3 months.

Step 1. Determine whether the product to be applied for is a KS certification object | Frist of all, confirm whether the product to be applied for is designated as a KS certified product, and whether KS standards and certification audit standards have been formulated * Korea National Standard Certification Comprehensive Information System (standard.go.kr) |

Step 2. Confirm factory audit review items | KS Q 8001 Appendix B Factory Audit Report Inspection Items and Evaluation Criteria |

Step 3. Introduce internal company standardization and quality management regulations | Corresponding to KS standards, certification audit standards, and internal standardization and quality management activities required in the factory audit report |

Step 4. The person in charge of quality management participates in regular training | Ensure that the person in charge of quality management meets the qualification requirements and participates in regular training (training of quality management leaders, training of management cadres) |

Step 5. Confirm production equipment and testing equipment | Production equipment, testing equipment and related company standard documents required for product production |

Step 6. Operation and management records of more than 3 months | Equipped with equipment and manpower according to the audit standard, it will operate normally and produce for more than 3 months |

Step 7. Apply for KS certification | Submit an application for certification to a certification body |

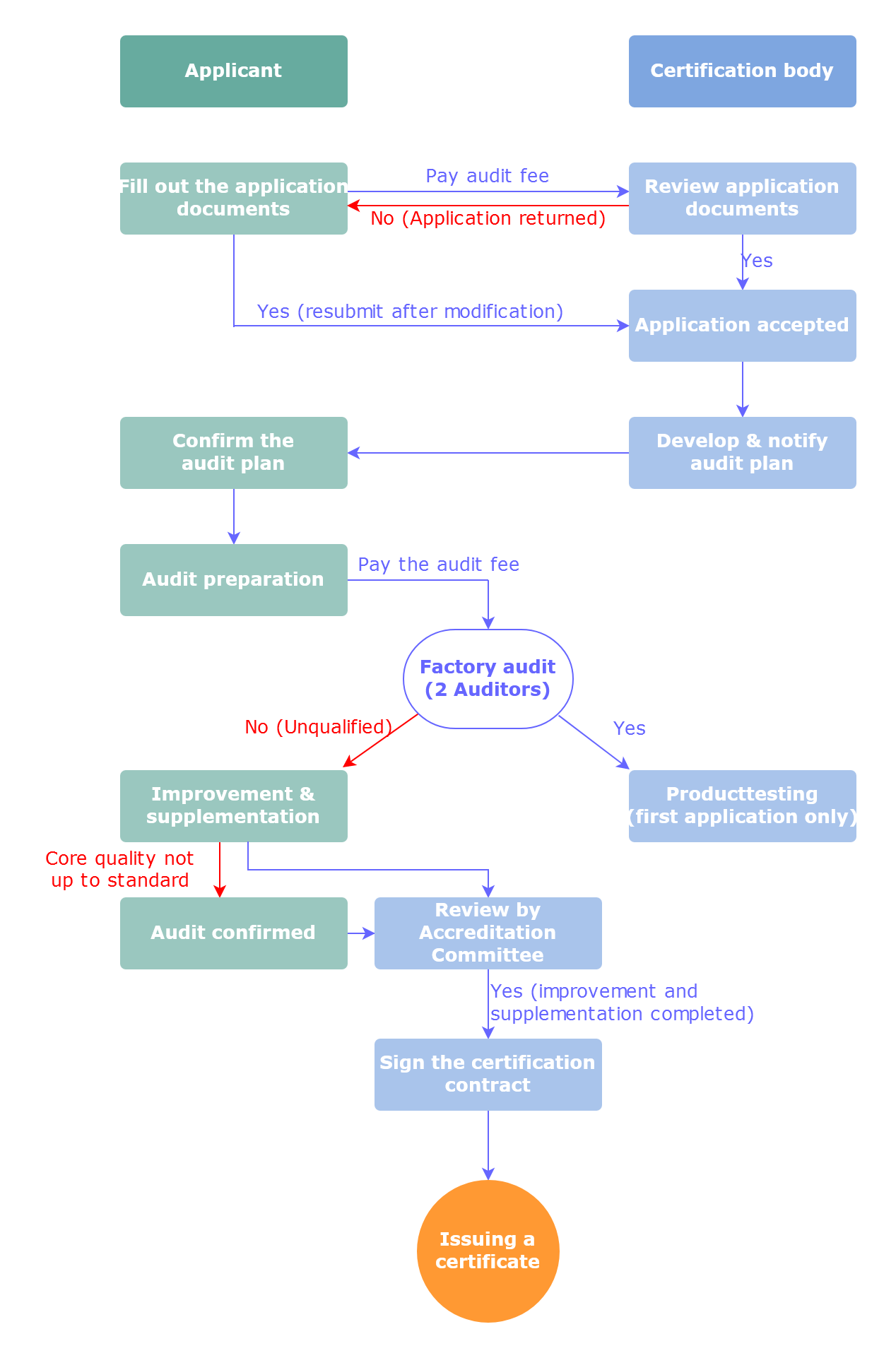

Product Certification Process

Application information

(1) When applying for certification:

- KS product certification application form (Korean/English application form provided by foreign certified companies)

- Certification application fee remittance certificate

- Manufacturing, inspection equipment catalog

- Raw material management catalog

- A copy of the business license

- Factory Registration Certificate

- Copy of ISO certification (for companies that have obtained ISO certification)

(2) During factory audit:

1. Company Profile (2 copies each)

- Company history, company profile, company management documents catalogue/QC flow chart, copy of business license and factory registration certificate;

- The original qualification certificate of the person in charge of quality management and the in-service certificate;

- Status of QM progress (QM activities, internal audits, proposals, training, customer complaints, 5S, environmental protection activities, safety management, etc.);

2. Factory overview, inventory, production and sales, production/inspection equipment conditions;

3. Company management documents/relevant Korean Industrial Standards (KS) and certification audit standards (latest revision)/reference and application standards, etc.

Certification fee and cycle

(1) Application fee: KRW 500,000 for one product (KRW 330,000 for each additional product)

(2) Factory audit fee: KRW 290,000/person/day (2 auditors, 2 days for 1 product, 3 days for 2~3 products, 4 days for more than 4 products)

(3) Travel expenses for reviewers: in accordance with the travel expenses regulations for level 5 civil servants in Korea (when reviewing foreign companies, air tickets and transportation costs are borne by the companies)

(4) Product testing fee: charged according to the fee standard of the relevant product certification and testing agency

(5) Cycle: 40 working days (excluding product testing cycle)